From PPE and hygiene to general safety and numerous industrial applications, rubber products increasingly form part of our everyday lives, with demand from consumers and industry resulting in higher expectations around performance and durability.

Key Benefits

Characteristics such as durability, elasticity and colour retention are just some of the ways we can significantly enhance the performance of rubber.

We combine chemical expertise with in-house testing to help both formulators and producers achieve their key performance objectives - whether this is to enhance an existing attribute or to help you develop an entirely new end product.

Durability, flexibility and high tensile strength make rubber a highly sought after material for a wide range of applications.

So, we set about creating advanced dispersion-based additives that can either enhance a particular attribute or supplement the development of an entirely new end rubber product.

The key element here is the use of accelerators, which help speed up the crosslinking process in the vulcanisation of natural or synthetic rubbers.

The Aquaspersions approach is to deploy water-based dispersions which can be easily incorporated into rubber latex to enhance performance and durability.

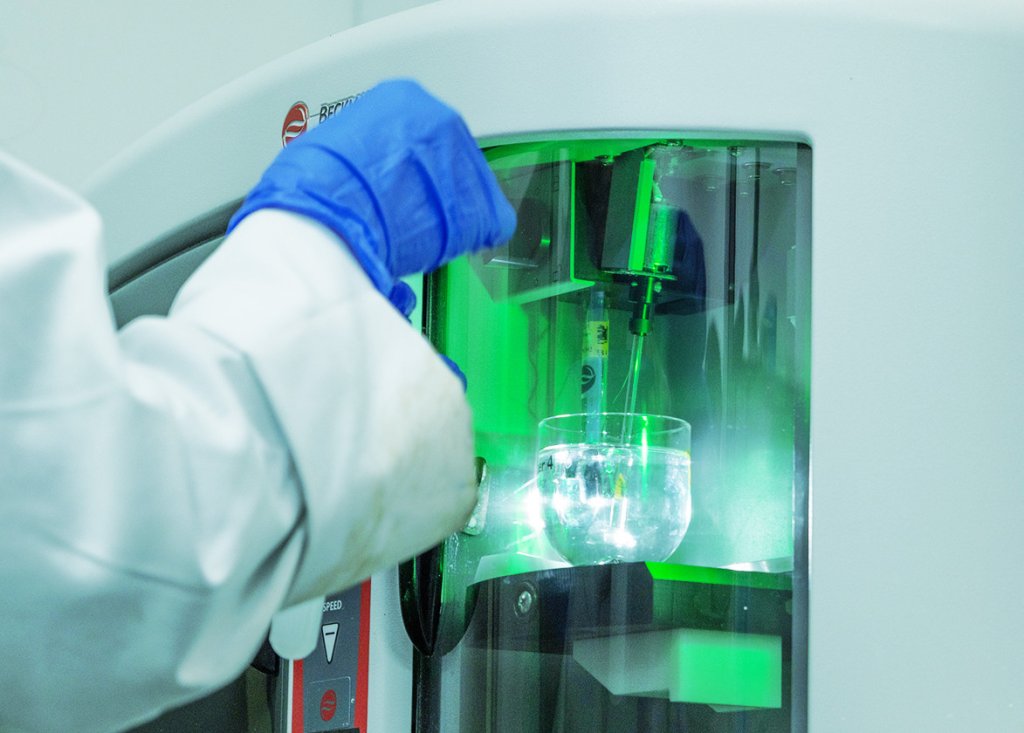

As part of the process, we test all the dispersions that we make to ensure they have the right physical and chemical properties.

Quality

Quality, consistency and dependability form the basis of everything we do. So, we set the same high standards across all our sites, with a right-first time approach through all our processes. We’re also guided by the ISO9001 standard for quality management, while ISO14001 ensures we measure and evaluate the impact of our products and processes on the environment.

Innovation

The challenges our customers are presented with continually drive us to find innovative solutions. So we never stand still. Our forward thinking approach to dispersion chemistry is based on rigorous research and development, product testing and a genuine collaborative approach.

By working with our customers, suppliers and end-users we can push our dispersion technology expertise to the next level to help you achieve the performance objectives of your products.

Explore our products

Explore our range of related products. These are just some initial recommendations, but use our search filter to find the specific product you need.